The Duty of Industrial Scales in Quality Control and Assurance

The Duty of Industrial Scales in Quality Control and Assurance

Blog Article

Enhance Your Business Workflow With Reliable Industrial Scales

In today's competitive landscape, the accuracy of industrial ranges plays an essential role in boosting general company procedures. Exact weighing not only mitigates expensive disparities across various sectors, such as production and logistics, but likewise ensures conformity with stringent market criteria. As companies look for to optimize effectiveness, understanding the different kinds of scales and their technical advancements ends up being crucial. Nevertheless, the option process can be complicated, and the effects of these choices can substantially influence operational success. What aspects should be taken into consideration to guarantee the ideal tools is chosen for your particular demands?

Relevance of Accurate Considering

Accurate weighing is important in numerous industrial applications, as even minor inconsistencies can result in substantial monetary losses and functional ineffectiveness. Industries such as production, logistics, and food processing depend upon accurate measurements to ensure item top quality, governing conformity, and ideal source administration. Unreliable weights can lead to overproduction, wastage of raw products, or poor supply, influencing earnings and client contentment.

Additionally, precise weighing is crucial for safety and security and environmental compliance. As an example, in the chemical sector, inaccurate measurements can bring about inappropriate mixes, resulting in unsafe circumstances or legal implications. Moreover, in the food industry, precise evaluating is vital for sticking to nutritional labeling needs, making sure that customers get exact info pertaining to the items they purchase.

The assimilation of trustworthy industrial scales not just boosts operational efficiency but additionally sustains data-driven decision-making. Spending in top notch industrial weighing remedies is critical for organizations aiming to maintain an affordable edge in today's dynamic industry.

Kinds Of Industrial Scales

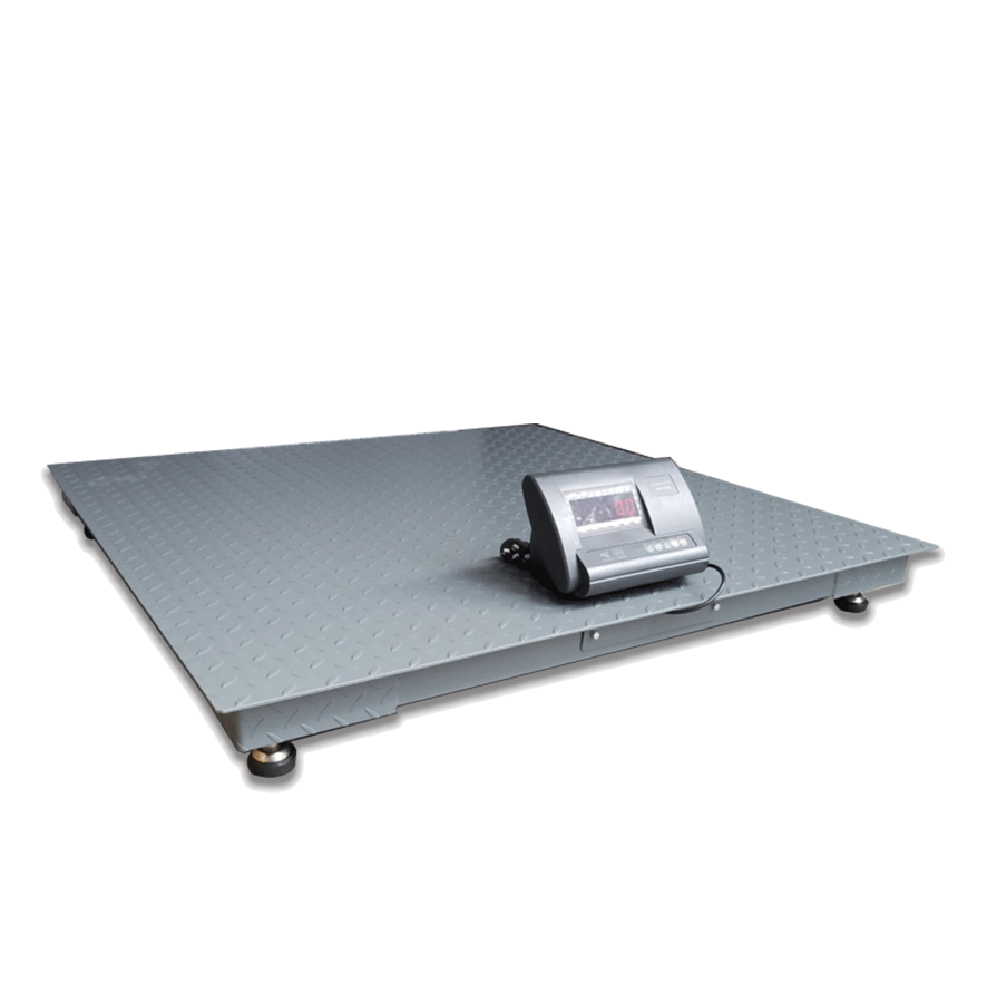

Industrial scales can be found in different types, each made to satisfy specific considering requirements across various industries. Amongst the most usual kinds are platform ranges, which provide a huge evaluating surface area appropriate for hefty products, making them ideal for stockrooms and producing facilities. These ranges typically include digital display screens for easy analysis.

Another kind is bench ranges, which are usually smaller sized and portable, excellent for use in research laboratories or retail environments. They enable quick measurement of smaller sized items while preserving precision. For applications requiring the evaluating of fluids, tank ranges are especially developed to determine the weight of tank, making sure specific inventory administration.

Crane scales are also noteworthy; they are suspended from a structure to weigh hefty products in commercial setups. Each kind of industrial scale serves an unique purpose, enhancing functional performance throughout diverse markets.

Benefits of Modern Technology

In addition, modern-day commercial ranges usually come outfitted with connection attributes that make it possible for smooth assimilation with various other systems, such as supply administration and manufacturing tracking. This interconnectivity promotes a more cohesive operations and decreases downtime, as organizations can check efficiency metrics and make data-driven choices quickly.

Additionally, many modern ranges use adjustable settings and straightforward user interfaces, enabling operators to adjust their devices for particular operational needs. Improved sturdiness and resilience versus rough environmental problems additionally add to the longevity and integrity of contemporary ranges, ensuring they can withstand the roughness of industrial usage.

Selecting the Right Equipment

Various industries may call for unique sorts of scales, such as flooring scales for heavy lots, bench ranges for smaller items, or mobile scales for flexibility. In addition, taking into consideration the atmosphere in which the scales will be made use of is vital. For example, equipment utilized in rough atmospheres might require to be sturdy and resistant to dust, wetness, or severe temperature levels.

Another important aspect is the innovation utilized in the ranges. Digital ranges commonly provide enhanced precision and ease of usage, while analog scales may suffice for less requiring applications. It is essential to review the scalability of the equipment, making sure that it can suit future growth or modifications in manufacturing procedures.

Lastly, services need to consider the track record and integrity of manufacturers, as buying high-grade equipment can result in long-lasting price financial savings and improved operational efficiency.

Upkeep for Durability

Routine upkeep is important for making sure the long life and optimum efficiency of commercial ranges. A systematic method to maintenance not only prolongs the life of from this source the devices however likewise ensures precise dimensions vital for functional performance.

Begin with regular examinations to recognize damage, ensuring components such as load cells and displays function appropriately. Calibration checks should be conducted routinely, ideally after significant changes in ecological problems or adhering to hefty use. Precise calibration is important for compliance with sector criteria and for keeping the dependability of weight dimensions.

Cleansing is an additional important element of maintenance. Dust, particles, and destructive compounds can impair efficiency and cause mistakes. Use appropriate cleaner and techniques to protect delicate elements. Additionally, it is advisable to establish an upkeep routine that tapes each service go to, calibration, and any kind of fixings executed. This paperwork aids in tracking tools find more info efficiency and planning for future maintenance needs.

Last but not least, training team on appropriate usage and care strategies will decrease the probability of operator mistake, further boosting scale reliability. By prioritizing regular maintenance, organizations can make sure that their commercial scales continue to be a trustworthy property in their operations.

Verdict

In recap, the integration of reputable commercial scales is necessary for boosting organization procedures throughout different markets. Routine maintenance and training additional contribute to the longevity and accuracy of these scales, cultivating data-driven decision-making and inevitably supporting general company success.

Industrial scales come in various kinds, each made to fulfill details considering demands throughout various industries. Crane scales are also significant; they are put on hold from a structure to weigh hefty products in industrial settings.Different sectors check out this site might need distinct kinds of ranges, such as floor scales for hefty tons, bench scales for smaller sized products, or portable ranges for adaptability - Industrial Scales. Digital scales frequently offer enhanced precision and ease of usage, while analog scales may be sufficient for much less demanding applications.In recap, the combination of reputable industrial ranges is important for boosting company procedures across numerous markets

Report this page